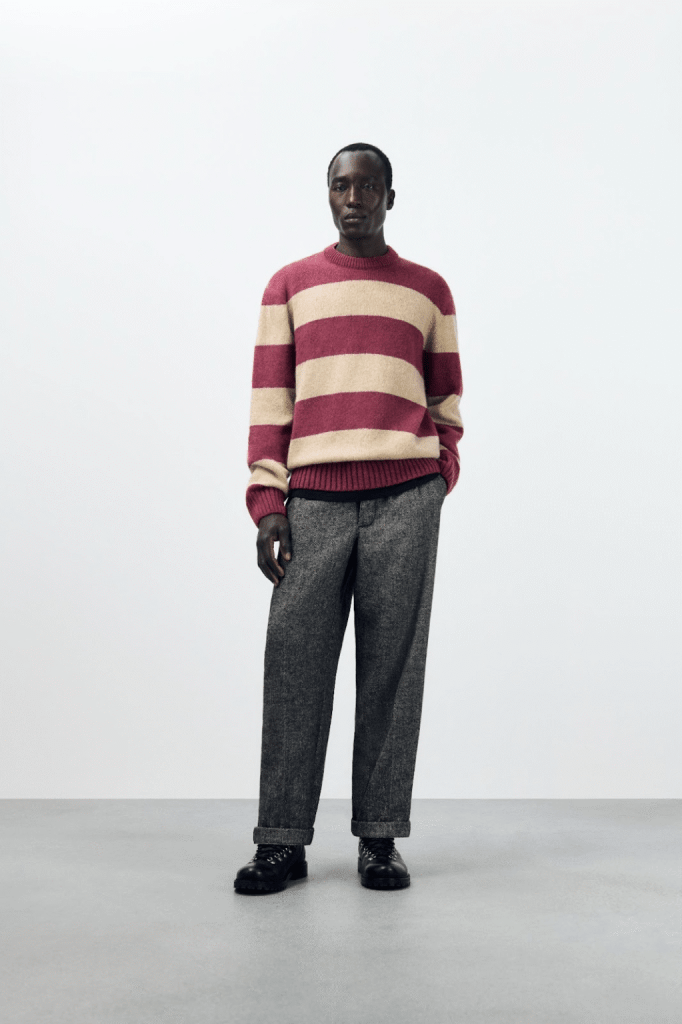

John Lewis has launched a “circular unisex knitwear collection” made from reclaimed and repurposed wool.

The 19-piece collection is created using wool collected through the John Lewis FashionCycle clothing take-back scheme, alongside material from similar schemes, which has then been used to produce new garments made by UK manufacturers.

Working with British wool recycler, iinouiio, John Lewis says the Closed Loop Initiative pushes boundaries in terms of design and craftsmanship. The collection is made up of five jumper designs as well as a beanie and scarf, all created from 100% recycled wool.

The pieces are knitted seamlessly on specialist circular machines, reducing production waste, and designed for further recyclability at end-of-life, minimising the environmental impact of each product.

“We’re so excited to introduce what we believe is a first among major UK high street retailers, combining expert craftsmanship with customer donations to create a collection that continues our circular journey. I know our customers will love the collection not only for the environmental impact but also for the carefully considered and playful design of each piece. This collection is not only kind to our planet but one that champions great British manufacture and craft, which we aim to continue supporting in the future.”

Megan Lovesey, Knitwear Buyer, John Lewis

Dr. John G. Parkinson, Co-Founder of iinouiio said, “Some people would interpret the materials that we work with at iinouiio as ‘waste’, but we’ve never thought so. Instead, we think of them as ‘raw materials’, too often limited by our skills and imagination. Our collaboration with John Lewis develops this idea into action with a unique initiative for retailing in the UK. We’re incredibly excited to see the collection land in shops and online.”

Bernie Thomas, Circular Economy and Sustainability Manager, SATCoL said, “Closed Loop is more than an initiative – it proves that British fashion businesses can lead the circular economy – transforming worn clothing and textiles into stunning new products, ready to begin their life all over again.”

How the production process works:

Step one: My John Lewis members drop off their pre-loved garments in any John Lewis shop to be resold or recycled using our FashionCycle scheme.

Step two: John Lewis’ FashionCycle partner, Salvation Army Trading Company (SATCoL), then collects and sorts the garments which are suitable for recycling, using their Fibresort Technology to separate the wool fibres.

Step three: Once the wool garments are sorted, they travel to iinouiio where they are cleaned, pulled, colour-matched and combined with other waste wool to prepare them for re-spinning.

Step four: Yarn spinners, Z. Hinchcliffe & Sons, then transform the recycled fibres into new recycled wool yarn by blending bespoke shades, spinning, twisting, and waxing.

Step 5: Expert knitters, Skinwear Ltd, knit the new yarn using waste-reducing circular knitting machines, individually hand-numbering each unique piece they create.

The Closed Loop Initiative will be available online and in six John Lewis shops (Oxford Street, Peter Jones, Edinburgh, Cambridge, Leeds and Cribbs Causeway) from today (29th September).

Leave a comment